Redesigning for Operational Efficiency

A UX Case Study in Real-Time Production Optimization

Collaborated with a cross-functional team of experts to research, design, and develop a modernized dashboard interface for a legacy manufacturing production line.

Applied user-centered design principles and incorporated data-driven insights to optimize the representation of real-time production data, enabling operators to make informed decisions and improve operational efficiency.

Project Overview

Bert Labs is an innovative technology company specializing in AI & IoT solutions for industrial optimization. We drive digital transformation, sustainability, and improved quality & safety in manufacturing through data-driven insights.

My Role & Approach

As the UX Designer on this project, my primary responsibility was to lead the research, design, and development of a modernized dashboard interface for the production line.

Developed user personas representing different roles within the paintshop (operators, supervisors, managers) to guide design decisions.

I conducted a competitive analysis of dashboard interfaces used in similar industrial settings. This allowed me to:

- Identify Industry Best Practices

- Benchmark Features and Functionality

- Uncover Emerging Trends

To gather in-depth user insights, I collaborated closely with experienced product managers and domain experts who had extensive knowledge of paintshop operations. These experts had direct contact with plant supervisors and directors, and their 20+ years of experience in various paintshops provided invaluable firsthand knowledge of user needs, pain points, and workflows. Through regular meetings and discussions, I was able to:

- Understand User Needs

- Identify Workflow Challenges

- Validate Design Decisions

Research & Discovery

To gain a deep understanding of the existing paintshop control system and identify opportunities for improvement, I embarked on a multi-faceted research phase.

Outdated interface with poor usability

Integrating the new dashboard with existing, potentially outdated, manufacturing systems or software.

Data Compatibility

Ensuring data from various sources (sensors, PLCs, etc.) could be seamlessly integrated and visualized in a meaningful way.

Lack of real-time data visualization

Addressing the inherent complexities of handling and displaying real-time production data.

Domain Knowledge

Understanding complex manufacturing processes and terminology to design an intuitive interface for operators

Bottlenecks in the Existing System

The existing system made it difficult for operators to pinpoint and address production bottlenecks

Diverse User Needs

Balancing the needs of different user groups (operators, supervisors, managers) with varying technical expertise and responsibilities.

Key Insights and Opportunities

Through a combination of research methods, including heuristic evaluation, competitive analysis, and consultation with subject matter experts, we identified several key insights and opportunities that guided our approach to redesigning the paintshop control dashboard

Ideation and Strategy

With a deep understanding of the existing system's challenges and user needs, we embarked on a phase of ideation and strategy development to guide the redesign of the paintshop control dashboard.

Developed user personas representing different roles within the paintshop (operators, supervisors, managers) to guide design decisions.

Restructured the information hierarchy to prioritize critical data and streamline workflows

Mapped out typical user journeys to identify pain points and opportunities for improvement.

Problem

The existing interface was cluttered, poorly organized, and difficult to navigate, hindering operators' ability to quickly locate and understand relevant information.

Solution

Redesigned the dashboard with a clear side navigation, optimized information architecture, and improved visual hierarchy to enhance usability and streamline workflows.

Redesigning for Operational Efficiency

A Complete Makeover Keeping The same Core values

The most tangible, delightful part of our process! All past research and ideation now come together to establish a successful, enjoyable user interface.

By transforming the cluttered and confusing legacy interface into a clean, organized, and user-friendly dashboard, we aimed to empower operators with the tools they need to monitor, analyze, and optimize production processes efficiently.

Problem

Operators lacked a centralized view of real-time production data and struggled to identify potential bottlenecks or inefficiencies.

Solution

Created a comprehensive dashboard that consolidates critical data points, provides real-time visualizations, and offers actionable insights for proactive decision-making.

Redesigning for Operational Efficiency

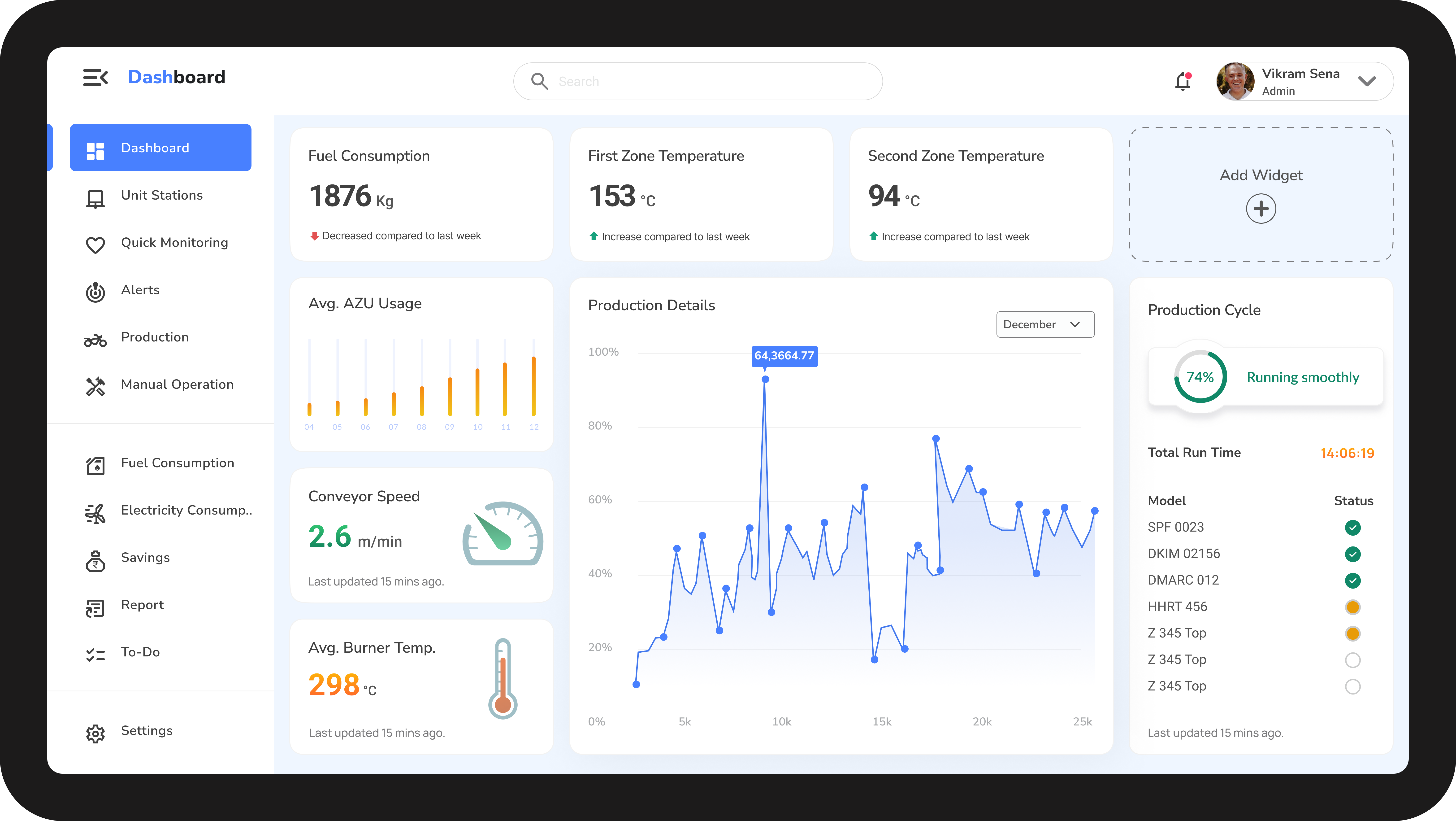

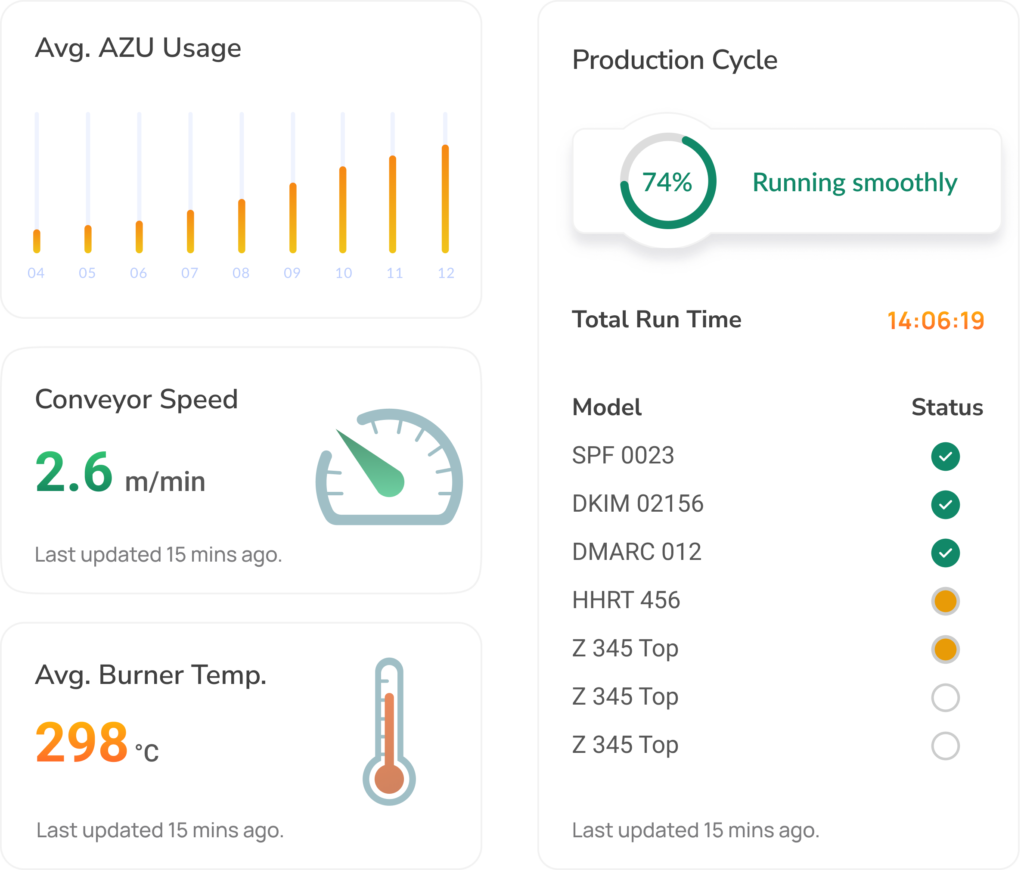

Dashboard Overview

The dashboard serves as the central hub for real-time monitoring of the paintshop's production line. By consolidating data from various sources into a single view, the dashboard eliminates the need for operators to navigate multiple systems or manually compile data.

Problem

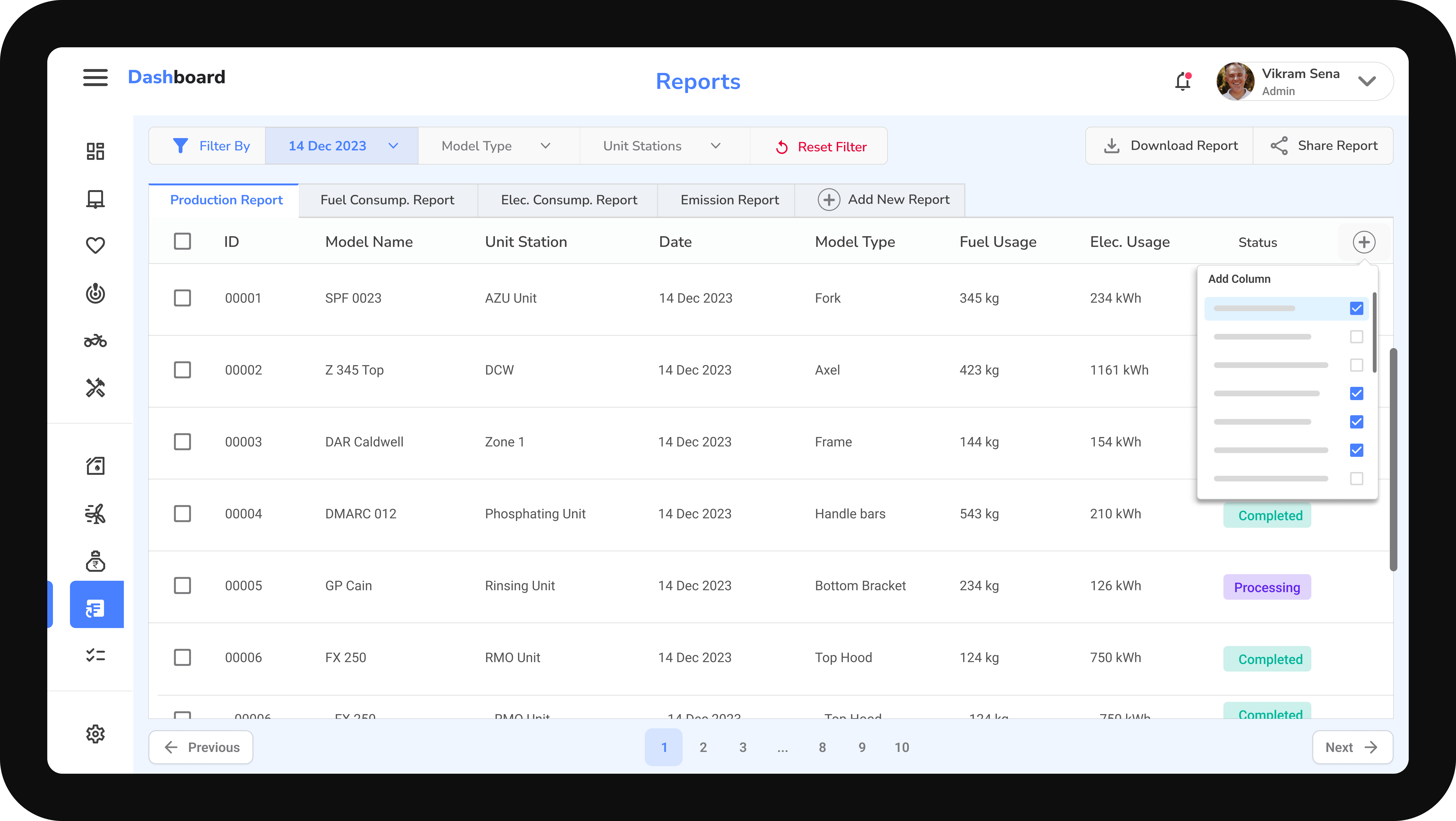

The previous reporting system was inflexible, difficult to customize, and lacked intuitive filtering options, making it time-consuming for users to access specific information.

Solution

Designed a modular and customizable reports screen with a clear tab structure, flexible filtering options, and the ability to create new reports tailored to specific needs.

Redesigning for Operational Efficiency

Personalized Report

By prioritizing flexibility, customizability, and ease of use, the redesigned reports screen allows users to efficiently access, analyze, and utilize production data to make informed decisions and optimize processes.

Problem

The existing interface required operators to switch between multiple screens to monitor unit stations and adjust control parameters, leading to inefficiency and potential errors.

Solution

Developed an integrated screen that combines unit station monitoring and control parameter adjustments, allowing for seamless navigation and real-time control.

Redesigning for Operational Efficiency

Manual Operation

This screen empowers operators with direct control over the production line, while providing clear visibility into key parameters and allowing for quick adjustments to optimize performance.

Relevant control parameters for each selected unit station are displayed alongside, enabling operators to make adjustments and fine-tune settings in real-time.

A primary goal of the project is to optimize energy usage within the paintshop. We will track and analyze data on fuel and electricity consumption to quantify the energy savings achieved through the new interface and its associated optimizations.

We aim to improve overall production efficiency by streamlining workflows, reducing downtime, and providing operators with real-time insights. Key metrics to monitor include production throughput, cycle time, and the number of units produced per hour.

Success Metrics

As the project is still in the proof-of-concept (POC) stage, the full impact of the redesigned dashboard on paintshop operations is yet to be realized.

However, the team has identified key success metrics to measure the effectiveness of the solution upon implementation: